AC Motors and Capacitors: How They Work Together

Capacitors may be small, but they play a big role in helping many AC motors run efficiently and reliably. Understanding what capacitors do (and how to spot problems) can help you keep equipment in good working order.

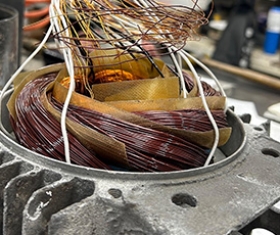

In simple terms, a capacitor stores and releases electrical energy. In AC motors, this stored energy is used to create the extra torque needed to start the motor or to keep it running smoothly. Without the right capacitor, a motor may struggle to start, run inefficiently, or overheat. Over time, a failing capacitor can lead to more serious issues, including motor damage, which can be costly to repair or replace.

Start vs. Run Capacitors

There are two main types of capacitors used in AC motors: start capacitors and run capacitors. Start capacitors provide a short burst of energy to get the motor turning. They are only active during the startup phase and then disconnect once the motor reaches its operating speed. Run capacitors, on the other hand, stay in the circuit while the motor is running, helping to maintain a steady and efficient current. This not only keeps the motor operating smoothly but can also reduce energy consumption. Depending on the application, some motors use only one type, while others require both to function effectively.

Common Applications

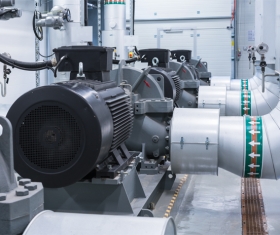

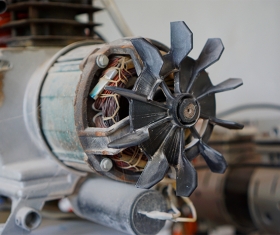

Capacitor-assisted AC motors are found in a wide variety of equipment. In homes, they are commonly used in heating and cooling systems such as furnace blowers and central air conditioning units. They are also a critical component in well pumps, sump pumps, and refrigeration systems. In commercial and industrial settings, you’ll find them in equipment like large fans, conveyor systems, and machine tools. Regardless of the environment, capacitors serve the same essential function—helping motors start reliably and operate efficiently.

Signs a Capacitor May Be Failing

Like all electrical components, capacitors can wear out over time. When this happens, you may notice that the motor struggles to start, takes longer than usual to get going, or produces a humming sound without any movement. In some cases, the motor may start but shut off unexpectedly during operation. Physical signs can also indicate a problem. If the capacitor casing is bulging, leaking, or showing signs of corrosion, it’s a strong indication that it needs to be replaced. Continuing to run equipment with a faulty capacitor can place unnecessary strain on the motor and lead to more extensive damage.

Troubleshooting and Safety

Diagnosing or replacing a capacitor requires caution, as capacitors store electrical energy even when the power is off. For this reason, testing or repairs should only be carried out by someone with the proper training and equipment. The power supply should always be disconnected before any inspection, and a meter designed for capacitance testing should be used to confirm the capacitor’s condition. If a replacement is needed, it’s important to use a capacitor with the exact type and rating specified by the motor’s manufacturer to ensure safe and reliable operation.

With decades of experience in motor diagnostics and repair, Gilbert-McEachern Electric can quickly identify capacitor issues, help with repair or replacement, and ensure your equipment is operating at peak performance. Whether it’s a furnace blower that won’t start, an air conditioning unit that’s running inefficiently, or an industrial machine showing signs of trouble, our team is here to help.

Reach out to learn more.